14. June 2016

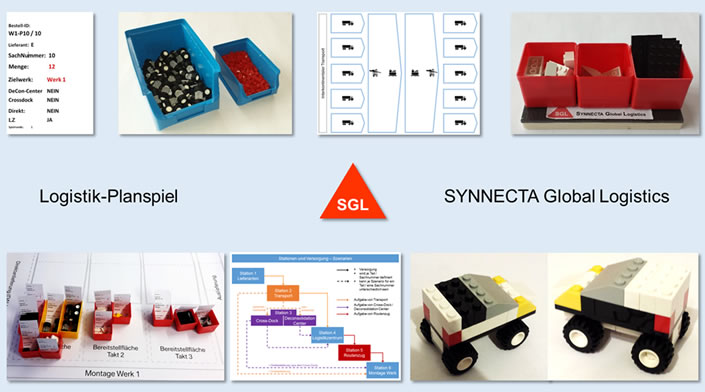

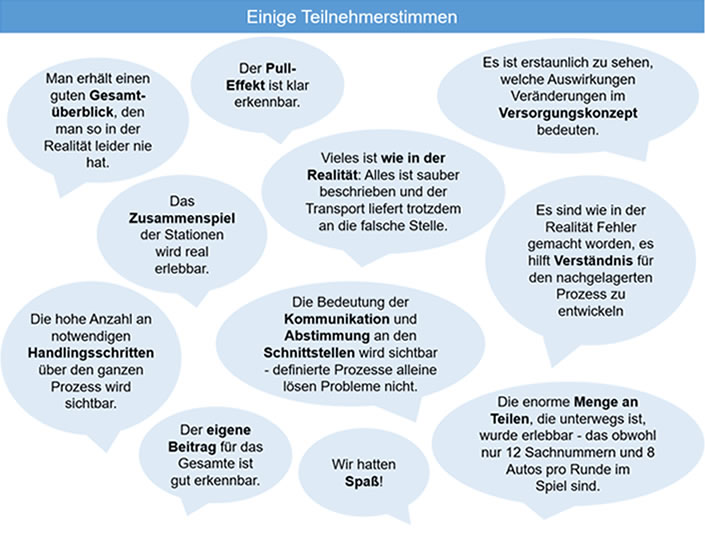

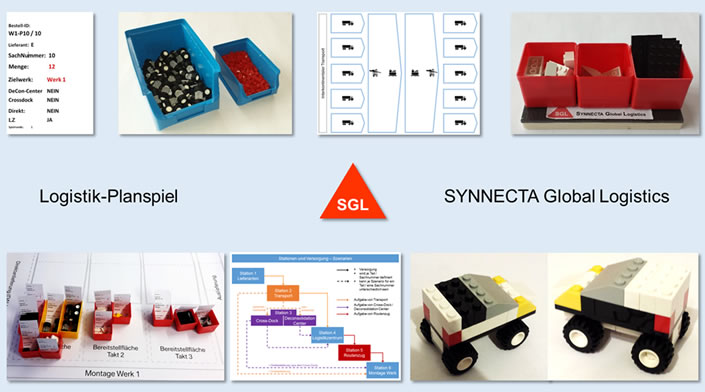

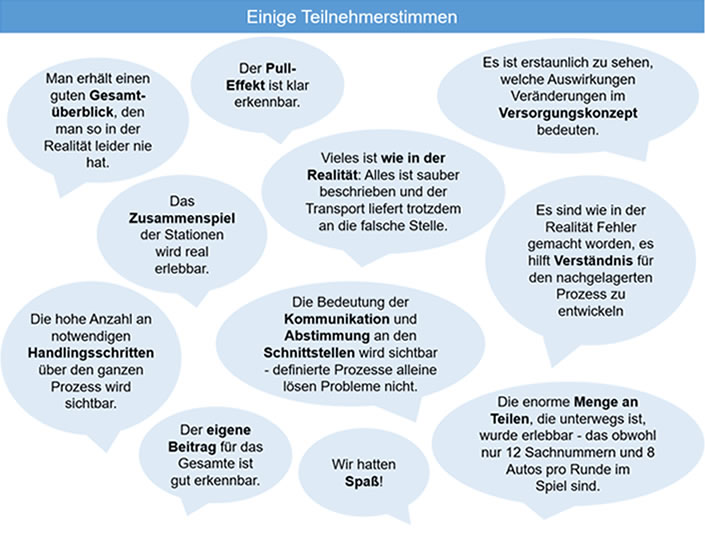

This is a game of six stations with set game boards and role ascriptions, thirty-five players, a range of supply concepts, several thousand Lego bricks, a great number of containers, lorries and ships. It is the goal of this game of quick rounds to produce eight Lego vehicles in three versions each according to a pre-determined production plan in two plants. »SYNNECTA Global Logistics« is a strategic simulation game that brings the full complexity of logistics to life.

If you are not a logistician, you won’t think it is so much of a challenge to deliver a component from a Chinese supplier to a German installation site.

Consider, however, that this component, together with thousands of other just-in-time components, needs to arrive – potentially in a particular order – at that installation site undamaged, having traveled around half the globe: being delivered by suppliers via a packaging service, placed into a container, going by ship to Europe, by lorry to a deconsolidation facility, put in intermediary storage to then go on again by lorry directly or via another, plant-internal storage stage… It is beginning to sound rather more complex and considerably more likely to fail! Yet a company’s logistics field will successfully supply in such by now global goods streams in about 99% of the cases.

It is nevertheless becoming more and more frequently impossible for individual logistics staff – especially at large companies – to maintain a complete overview of these highly complex global streams with countless parts and a range of material flows and supply paths and therefore to fully understand the contexts and dependencies.

That is why we developed this strategic logistics game in the course of a client project. The fundamental goal of this game is to allow the players to fully experience the entire logistics chain and the repercussions of different supply concepts. It also, obviously, covers topics such as interface coordination, communication, cooperation and, last but not least, is fun for the participants.

Between 25 and 40 employees can play our strategic game together and experience the logistics chain: beginning with a range of suppliers, they move on to transport, elements of delinkage and internal plant logistics, and eventually construct Lego vehicles. The supply concepts can be altered in the course of the game. The repercussions of such adaptations are immediately felt by the participants. Playing time for each game is about half a day, including reflection and application to practical experience.

If you wish to gain more detailed insight, we will be delighted to send you our strategic game concept. Please contact Thomas Meilinger, E-Mail: meilinger@synnecta.com

6. July 2015

»The purpose of understanding your privilege isn’t to make you feel something. Not guilt, not shame, not anything else. It’s to help you understand that you have a set of things you take for granted that other people don’t have, so that you can change the way you act.« SYNNECTA – Diversity. Workshop »Sexuelle Identitäten« on the occasion of the Cologne Pride. And it is proofed – beeing in the midst of Diversity with your whole beeing makes a difference and let you understand.

»The purpose of understanding your privilege isn’t to make you feel something. Not guilt, not shame, not anything else. It’s to help you understand that you have a set of things you take for granted that other people don’t have, so that you can change the way you act.« SYNNECTA – Diversity. Workshop »Sexuelle Identitäten« on the occasion of the Cologne Pride. And it is proofed – beeing in the midst of Diversity with your whole beeing makes a difference and let you understand.

Cologne Pride 2015

3. December 2014

You don’t have to look far to find instances of the world of VUCA. One of the most immediate examples are production supply processes: logistics. Volatile markets, uncertain conditions, complex production systems and ambiguous parameters for decision-making demand new skills.

You don’t have to look far to find instances of the world of VUCA. One of the most immediate examples are production supply processes: logistics. Volatile markets, uncertain conditions, complex production systems and ambiguous parameters for decision-making demand new skills.

A look at our clients reveals that an organization’s logistics sector is increasingly becoming its success factor. Logistics areas are growing disproportionately, transport costs are rising, client and delivery networks are becoming ever more global. Nevertheless, we still frequently encounter the notion that logistics are merely a service at the end of the process chain, not a driver at the spearhead of change.

In reality, we see that logistics has long since moved into the focus of top management. We have noticed a considerable increase in client requests for change accompaniment in logistics processes, particularly so in the automotive sector. Usually, they come together with a demand for qualification and the creation of logistics skills.

At SYNNECTA, a small group of experienced consultants have specialized in change management and logistics process training. Logistics projects put us at the exciting interface between the internal and external worlds, between client demands and delivery networks, between process optimization and plant harmonization. We see the trends of our society reflected in the logistics sectors of organizations: they are an indicator for change and future developments.

With the increasing concentration on key skills (make or buy) and resulting strategies to outsource, delivery chains are more and more frequently based on a division of labour. Sharp competition on global markets, short product life cycles and high client demand foster the steep rise in the number of derivative products: supply guarantees in combination with highly flexible delivery chains are moving into the focus of managerial decision-making.

Supply chain management has thus become an important component of an organization’s planning and management. Elements of logistics structures such as cross-docks, automatic small parts warehouses and tugger trains demand innovative processes, great investments and complex system landscapes as well as, importantly, behavioural change and entirely new standards of management. We have methodical answers:

- Insight images provide us with a view of the entire process chain and clearly depict its complexity.

- Planning games bring the reality of logistics into the seminar room and clarify, e.g., bull-whip effects and how best cost country sourcing and parts availability are related.

- Puzzles help develop an understanding for lean processes, value streams and line back principles.

- Defamiliarization opens up new points of view, networks create synergies.

- Complexity is not confused with complication; we respond with simplicity and standardization.

- SYNNECTA events formats pick up flow, pulse and rhythm.

- Logistics connect: we understand processes and we can do people.

Renate Standfest

3. December 2014

Bangalore, 27 degrees Celsius, hustle and bustle on the busy streets, the sun is shining on an urban soundscape. We, the participants of the conference, notice none of this. Air-conditioning has cooled the windowless conference rooms down to a temperature of sixteen degrees. It is too cold for heated discussions, but there is an atmosphere of critical and constructive grappling with current issues related to »Beyond Learning – L&D as Architect of Sustained Organization Development«. The atmosphere and the conversations are concentrated, interested, open and friendly.

Bangalore, 27 degrees Celsius, hustle and bustle on the busy streets, the sun is shining on an urban soundscape. We, the participants of the conference, notice none of this. Air-conditioning has cooled the windowless conference rooms down to a temperature of sixteen degrees. It is too cold for heated discussions, but there is an atmosphere of critical and constructive grappling with current issues related to »Beyond Learning – L&D as Architect of Sustained Organization Development«. The atmosphere and the conversations are concentrated, interested, open and friendly.

In October, we were invited by the Indian NHRD to participate in the 2nd National Summit on Learning & Development in Bangalore as official knowledge partners. Surrounded by Indian HR staff, psychologists, managers, decision-makers, leadership architects, organizational consultants and students of a business school, we were conspicuous as the only non-Indians in the room. What does it mean to be invited to an Indian conference as a German knowledge partner? What did we experience there and how does that experience impact our work?

The conference was driven by questions of how to deal with VUCA in global conditions and after the sense of human activity and organizational design. The answers contained one assumption: that organizational structures occur through humanness and togetherness in interaction. Hence, the design of relationships is more important than the defence of personal aims when it comes to achieving sustainable action within organizations. In Rüdiger Müngersdorff’s panel »Transformation – Role of L&D – From Solution Provider to Proactive Influencer of Change«, the speakers agreed that it was the proactive behaviour of individuals that made change and variation possible in organizations in the first place and that L&D departments had to be equipped with the according tools and skills in order to enable action. This includes the ability to implement participation concepts as bottom-up architectures: an ability that is currently being lost in a time of top-down, cascading concepts. All participants agreed that vibrancy, agility, alertness, speed can only be developed from within the organisation: middle-bottom up.

We were inspired by insights and statements like the following:

- Participation: VUCA can only be adequately met when all persons in an organization are able to participate. VUCA is not a problem of the subject, but a structural global phenomenon that needs to be addressed from out of the logic of the collective. The performance of an individual only attains its significance in the context of others and has to be motivated by the question of shared values.

- Spirituality: every-day activity derives its meaning from spiritual motivation; shared values are a basic condition for designing organizations. Spirituality is not an end in itself.

- Willingness to change: There is one important prerequisite to learning: unlearning. That includes an awareness of the given conditions and the willingness to undergo a proactive transformation.

What was surprising? The term VUCA and all its levels of interpretation were a key topic. All panels shared the characteristic that they critically addressed conventional L&D strategies: Classic management and senior leadership with all its dominant elements was questioned and participation and organizational development across barriers of function and hierarchy advocated.

To us, every encounter with people, their topics and attitudes always means intercultural and transcultural learning. Such encounters take us away from theoretical analysis and bring us into the midst of direct experience, influencing our notions of the worlds. With our Pashminas still wrapped around us, we return with new strength to the German winter, having gained new stories and enriching perspectives on ourselves and on others.

Hanna Göhler

www.nationalhrd.org

3. December 2014

The SYNNECTA Qualification Offensive goes to China

An innovative, dialogue-oriented logistics training… in China. Is that possible? There are plenty of stereotypes about learning in China, including positive ones. However, they certainly do not include interaction between »teacher« and »students«, working on a par, fostering productive chaos and creativity. Yet, being who we are – SYNNECTA – we wouldn’t allow such stereotypes to stop us.

The background: Since 2011, we have been working with a premium automotive manufacturer to establish a modern logistics system. In our times, lean logistics processes significantly shape the success of the entire production process as a growing number of models, derivative products and production sites have increased complexity. In other words, logistics processes are significant to progress, innovation and the future success of the entire business. Next to the need to safeguard supply for the production, ever greater significance has also been awarded to cost, efficiency and process stability.

This means »hard« changes, such as optimizing and streamlining processes, raising flexibility and reducing storage spaces on the assembly lines, but also a new mindset in logistics organization. A fundamental rethink is required of all concerned. The employees have to gain an overview of the entire process and at the same time take responsibility. What needs to be sharpened is not only the establishment of logistics planning itself, but also an awareness of how such planning needs to be approached in the first place.

The SYNNECTA Learnshop

We do not want to train employees the classic way: we want to enable them to release knowledge out of themselves and to establish a new mindset in a bottom-up workshop. Initially, we do not address each production site separately (»heterogeneity instead of functionality«). We bring together employees and managers from all plants and all functions to take part in a two-day Learnshop. One SYNNECTA member teams up with an expert from the organization in order to enable all participants to learn and work together as well as learning about the culture of learning itself and experimenting with it.

In 2012, an international roll-out was started in Europe, the USA and Africa. What was special about it was that we reacted to this multicultural challenge with inter-cultural competence: a typical SYNNECTA response. We placed a »native speaker« into each of the sites abroad in order to »translate«, break down cultural barriers and address the participants according to the conventions of their own country. The results went far beyond the enactment of new strategies. The entire organisation was vitalized and long-term learning enabled. Evaluation feedback was outstanding.

We aimed to achieve the same results in the plants in China. To our surprise, our »bottom-up« approach turned out to be the smaller problem. China is undergoing great change and there are many young, open people who are more than willing to learn. Our approach moreover made it possible to address cultural barriers and engage in our client’s organizational culture. In order to dissolve the remaining cultural barriers, our first step was not to present our approach, but to listen carefully to our client in order to engage with their organizational culture. This way, we were able to eventually offer customized trainings that addressed their needs. Not least, it was important that we were able, as usual, to work in two languages: we called upon our consultants Detlef Däke and Thomas Meilinger as well as SYNNECTA consultant and native speaker Vicky Qian.

As a young, growing consultancy business without a long-standing reputation on the Chinese market but with a very well-trained Chinese team, we had to set out by earning a positive opinion of our competence. We were soon able to wow our client. We achieved that by enabling vibrant group dynamics and intense interaction, working with real and concrete case studies during the workshops.

Our approach was unusual for Chinese organizational culture. The Chinese market is fast and dynamic and companies tend to find rapid solutions for those problems that smart the most at any given moment. Vicky Qian: »Most organizations are fighting for survival. They want to take care of products, profit, the market. We, on the other hand, take care of the people, of bringing culture into the organization. This does not offer organizations a rapid solution, however: it gives them long-term paths on which they learn to recognize the relevant changes early on, to lead their employees and to continue to develop the culture as a whole.«

In the first two events, altogether 120 participants were given an insight into the processes in international logistics networks with the aid of a process image as the Big Picture. The participants were furthermore encouraged to critically question these processes. At the same time, we employed innovative dialogue methods in order to foster the development of ideas: encouraging the exchange of experience and the ability to absorb new perspectives whilst avoiding dry specialization trainings.

The careful adaptation of our methods to cultural needs and specificities are a way of effectively communicating not only change and management issues, but also demanding specialist concepts. Before this very year is out, we will conduct another three Learnshops with 180 further employees. In the Chinese production plants, our client’s logistics restructuring is already well under way. Our client’s great satisfaction already speaks for itself. We feel that our Chinese colleagues’ high skills set is a great gain. Diversity opens new perspectives; that is also true in local consultancy teams.

»The purpose of understanding your privilege isn’t to make you feel something. Not guilt, not shame, not anything else. It’s to help you understand that you have a set of things you take for granted that other people don’t have, so that you can change the way you act.« SYNNECTA – Diversity. Workshop »Sexuelle Identitäten« on the occasion of the Cologne Pride. And it is proofed – beeing in the midst of Diversity with your whole beeing makes a difference and let you understand.

»The purpose of understanding your privilege isn’t to make you feel something. Not guilt, not shame, not anything else. It’s to help you understand that you have a set of things you take for granted that other people don’t have, so that you can change the way you act.« SYNNECTA – Diversity. Workshop »Sexuelle Identitäten« on the occasion of the Cologne Pride. And it is proofed – beeing in the midst of Diversity with your whole beeing makes a difference and let you understand. You don’t have to look far to find instances of the world of VUCA. One of the most immediate examples are production supply processes: logistics. Volatile markets, uncertain conditions, complex production systems and ambiguous parameters for decision-making demand new skills.

You don’t have to look far to find instances of the world of VUCA. One of the most immediate examples are production supply processes: logistics. Volatile markets, uncertain conditions, complex production systems and ambiguous parameters for decision-making demand new skills. Bangalore, 27 degrees Celsius, hustle and bustle on the busy streets, the sun is shining on an urban soundscape. We, the participants of the conference, notice none of this. Air-conditioning has cooled the windowless conference rooms down to a temperature of sixteen degrees. It is too cold for heated discussions, but there is an atmosphere of critical and constructive grappling with current issues related to »Beyond Learning – L&D as Architect of Sustained Organization Development«. The atmosphere and the conversations are concentrated, interested, open and friendly.

Bangalore, 27 degrees Celsius, hustle and bustle on the busy streets, the sun is shining on an urban soundscape. We, the participants of the conference, notice none of this. Air-conditioning has cooled the windowless conference rooms down to a temperature of sixteen degrees. It is too cold for heated discussions, but there is an atmosphere of critical and constructive grappling with current issues related to »Beyond Learning – L&D as Architect of Sustained Organization Development«. The atmosphere and the conversations are concentrated, interested, open and friendly.